Global Surface Enhancement Technologies for PCR Plastics Market Outlook 2026-2036: Strategic Trends

Global Surface Enhancement Technologies for PCR Plastics Market Projected to Reach USD 1.4 Billion by 2026

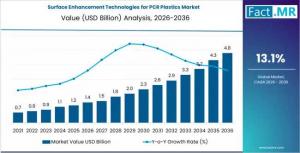

UNITED STATES, MD, UNITED STATES, January 20, 2026 /EINPresswire.com/ -- As the global manufacturing sector pivots toward a "Circular Plastics Renaissance," the Surface Enhancement Technologies for PCR Plastics Market is emerging as a critical bridge between sustainability mandates and high-performance product requirements. According to recent industry analysis, this specialized market is projected to reach USD 1.4 billion by 2026, expanding at a robust compound annual growth rate (CAGR) of 13.1% through 2036.The surge in demand is driven by the urgent need to elevate Post-Consumer Recycled (PCR) plastics to virgin-quality standards. While PCR materials are essential for meeting the EU Packaging and Packaging Waste Regulation (PPWR) and various global Extended Producer Responsibility (EPR) mandates, they often suffer from surface energy variability, "blooming" of legacy additives, and aesthetic inconsistencies. Surface enhancement technologies—ranging from plasma and laser texturing to nano-coatings—are now the primary solutions enabling the use of recycled content in premium sectors like consumer electronics and luxury packaging.

Request for Sample Report | Customize Report |purchase Full Report - https://www.factmr.com/connectus/sample?flag=S&rep_id=13711

Overcoming the "Composition Trap" with Advanced Engineering

Historically, the adoption of PCR plastics was limited by their inferior surface properties, which hindered the adhesion of paints, adhesives, and protective finishes. Today, a suite of "surface-first" technologies is redefining these material limits:

Plasma and Laser Texturing: Currently accounting for a significant portion of the market, these processes modify the molecular structure of the plastic surface to increase energy and ensure durable bonding.

UV and Nano-Coatings: Advanced UV-stabilized systems and sol-gel nano-coatings are being deployed to provide scratch resistance and optical clarity, crucial for high-end electronic housings and cosmetic containers.

Nano-Dispersion & Compatibilization: Technologies utilizing carbon nanotubes (CNTs) and graphene-based additives are improving the structural integrity and thermal stability of recycled resins, making them competitive with virgin engineering plastics.

Strategic Market Segments and Regional Growth

The market is currently bifurcated by application, with cosmetic and premium packaging and consumer electronics leading the adoption curve. In the electronics sector alone, the demand for PCR resin used in device housings is expected to grow as brands like Acer and Apple integrate up to 50% recycled content into their hardware.

Regionally, the Asia-Pacific market is set to witness the fastest expansion. India is projected to lead with a 15.6% CAGR, fueled by a domestic manufacturing boom and aggressive government plastic bans. Meanwhile, the United States and Germany remain innovation hubs, focusing on high-throughput coating lines and low-VOC (volatile organic compound) systems to align with stringent ESG (Environmental, Social, and Governance) strategies.

Industry Leadership and Innovation

Key players at the forefront of this technological shift include global chemical and material science leaders such as BASF, Evonik, Covestro, Cabot, and Mitsubishi Chemical. These companies are moving beyond simple recycling to offer "Circular CMF" (Color, Material, Finish) guides that help designers integrate circularity without sacrificing aesthetic appeal.

"The challenge of implementing PCR plastics is no longer just an engineering hurdle; it’s about overcoming consumer preconceptions through superior finish and durability," notes a recent industry report. "Surface enhancement is the invisible layer that makes sustainability invisible to the end-user."

Future Outlook: A 2026 Inflection Point

As the industry approaches 2026, the shift toward mono-material designs and blockchain-enabled traceability is expected to further catalyze the surface enhancement market. By simplifying the underlying substrate and focusing on surface-level performance, manufacturers can ensure that products remain fully recyclable at the end of their life cycle, creating a "Truly Circular Loop."

With the global PCR plastic packaging market alone headed toward an USD 87 billion valuation by 2035, the technologies that "enhance" these materials are no longer optional—they are the new standard for modern manufacturing.

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us – sales@factmr.com

To View Related Report :

3D Printing Plastics Market

https://www.factmr.com/report/3796/3d-printing-plastics-market

Transparent Plastics Market

https://www.factmr.com/report/4408/transparent-plastics-market

Aerospace Plastics Market

https://www.factmr.com/report/4736/aerospace-plastic-market

Mushroom Plastics Market

https://www.factmr.com/report/5437/mushroom-plastics-market

About Us:

Fact.MR is a distinguished market research company renowned for its comprehensive market reports and invaluable business insights. As a prominent player in business intelligence, we deliver deep analysis, uncovering market trends, growth paths, and competitive landscapes. Renowned for its commitment to accuracy and reliability, we empower businesses with crucial data and strategic recommendations, facilitating informed decision-making and enhancing market positioning.

S. N. Jha

Fact.MR

+ +1 628-251-1583

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.